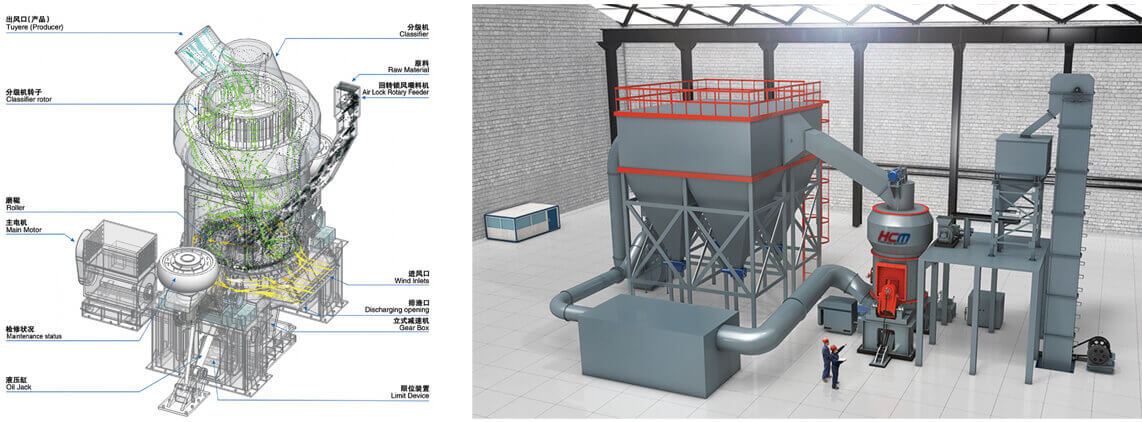

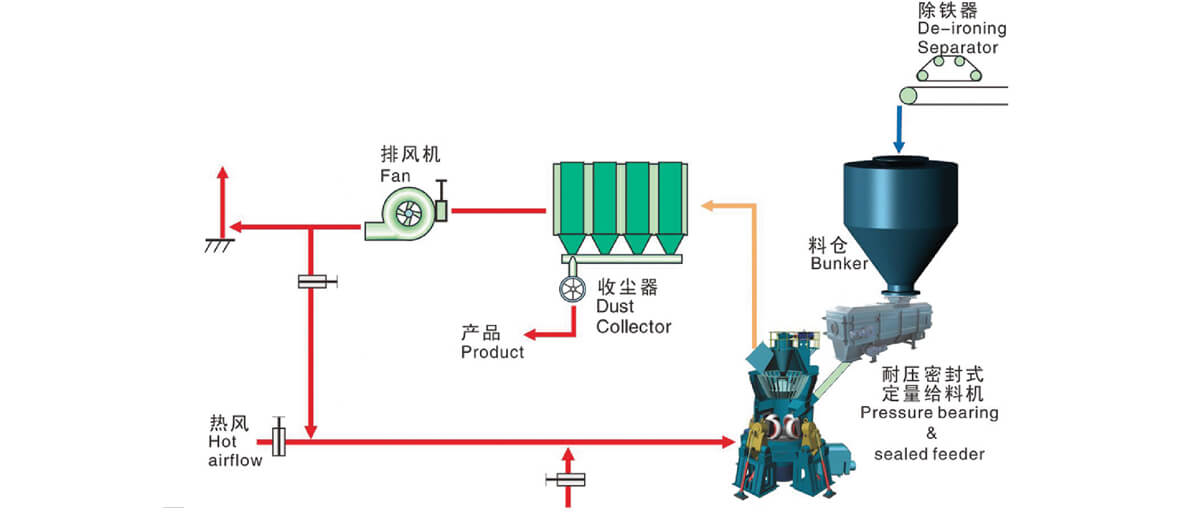

Chigadzirwa chekupedzisira chine hunhu hwakagadzikana. Nguva pfupi yekushandiswa kwechinhu ichi kugayiwa inogona kuita kuti chive nechimiro chakaenzana uye kuyerera kwakanaka. Iron shoma iri nyore kubvisa kuitira kuti ive nechokwadi chekuchena kwakanyanya uye kuchena.

nzwisisa

UNODA GADZIRIRO YOSE?Kuti uwane rumwe ruzivo nezvechigayo chekukuya kana chikumbiro chemutengo, ndapota taura nesu.

Kubvunzataura nesu

Kugamuchirwa kuGuilin HongchengGuilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Runhare:86-15107733434

- Kero:Yangtang Shanshui Industrial Park, Xicheng Economic Development Zone, Guilin City, Guangxi Province, China

- E-mail:hcmkt@hcmilling.com

- Nhare:+91 97125 28918

- E-mail:hgvala@gmail.com

Mutungamiriri wekushambadzira weIndia

© Kodzero Dzese Dzakachengetedzwa - 2010-2025.Zvigadzirwa Zvinopisa - Mepu yenzvimbo

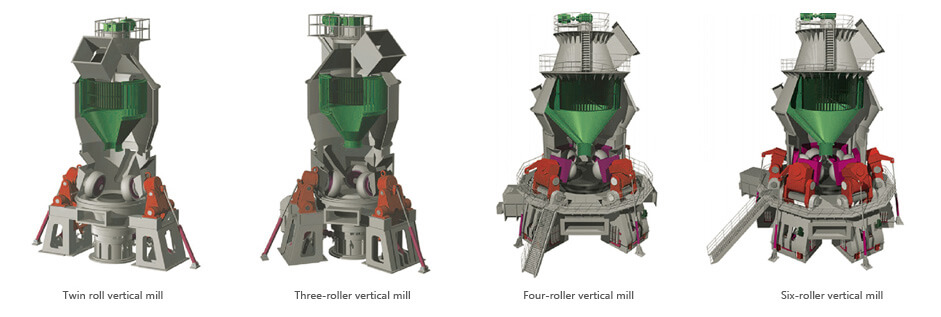

Kukuya kweMarasha, Chigayo Chekukuya Chakanyanya Kunaka, Chigayo Chakanaka Zvakanyanya, Chigayo chePetroleum Coke Vertical Roller, Muchina wekugaya, Muchina wekugadzira pendi yeupfu kubva kuChina,

Kukuya kweMarasha, Chigayo Chekukuya Chakanyanya Kunaka, Chigayo Chakanaka Zvakanyanya, Chigayo chePetroleum Coke Vertical Roller, Muchina wekugaya, Muchina wekugadzira pendi yeupfu kubva kuChina,